Previously, I wrote a blog about industrial vibrator options for hot temperature applications like transfer chutes in forging facilities or installations on cope & drags in a foundry. But what about those applications on the other end of the temperature spectrum?

Let’s talk about those cold environment applications like outdoor installs on a silo, chute, or load-out spout in geographic locations that face frigid temps, hopper bottom trailers delivering goods when there’s snow on the ground, or within facilities that do not have climate control.

When frigid temps are a factor, we lean towards supplying an electric vibrator option for material flow issues. Electric industrial vibrators do not require compressed airlines to operate, which is the biggest drawback when using pneumatic vibrators for these application environments.

Between RE Rotary Electric Vibrators, CM Electromagnetic Vibrators, and DC Vibrators, plenty of voltage options, force outputs, and frequencies are available.

Rotary Electric Vibrators

These are fantastic material flow solutions for clogged pipes exposed to the elements as well as on the sides of hoppers and bins experiencing ratholing of bridging. There are a few different mounting options available that can address both types of applications.

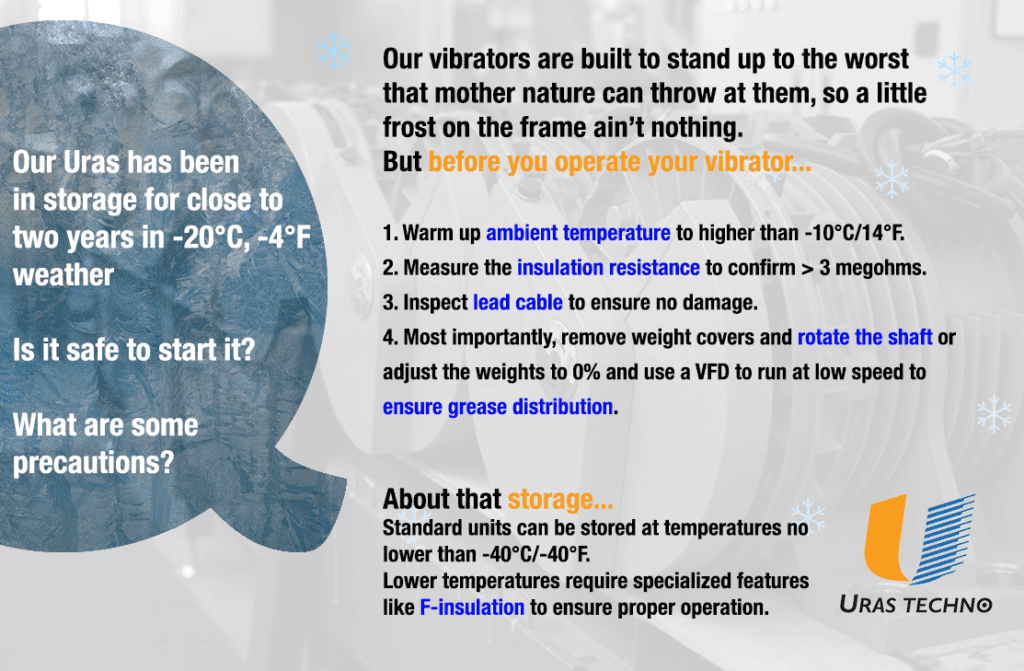

Rotary Electric Vibrators can operate in temperatures as cold as 14F (-10C) when cold-started. When the unit is warmed up prior to operation, it could be used in temperatures as low as -40F (-40C). If your unit will consistently operate in frigid temps, its circuits can be wired to a switch that will allow the vibrator to warm itself up.

Here are a few precautions you can take to protect your motor if you are operating your motor in cold temperatures:

A circuit diagram can be supplied to instruct the installer on how to connect the unit’s wires to both a circuit and switch mechanism, which will give the unit’s windings the ability to heat up without turning on the unit. Once the windings are at a suitable temperature, the unit will turn on to deliver vibration to the medium to which it is attached.

This relatively cheap and simple solution allows the industrial vibrator to be used in any cold temperature.

Another pro of this product line is the mounting flexibility. If you are looking to keep material moving in your industrial chute or pipe, Pipe Bracket Assemblies are great! They do not require permanent mounting or welding for installation. This gives you the ability to move the bracket freely to the problem areas.

There are a wide range of force and frequencies available with IP55/IP66 ratings. Uras Techno’s lines of Rotary Electric Vibrator, which are distributed by The Cleveland Vibrator Company in the U.S.A., offers:

- A standard 3-year warranty

- All-weather phthalic acid resin coating finish

- ISO 9001 quality standards

- Ratings for continuous duty with a fully enclosed construction that offers protection from environmental elements

CM Electromagnetic Vibrators

These units work great as material flow aids on small hoppers, chutes, or flow pipes.

Electromagnetic vibrators are designed and built to withstand operational temps as low as -58F (-40C).

The design of this model includes unitized armature assemblies composed of strong fiberglass leaf springs and an encapsulated coil. It also has a strong aluminum mounting base and housing that offers protection from the elements and ensures safe operation.

The unit can be fitted with controllers for adjusting vibration force and frequency. This gives you the flexibility to fine-tune the vibration that best suits your application and material type. The video below does a great job of showing these controls in action.

Compared to the RE Rotary Electric’s continuous duty rating, Electromagnetic vibrators have duty cycle limitations. It is recommended to not exceed 8 hours of operation within a 24-hour period.

This solution works best for small amounts of material and applications that allow material to flow with assistance from gravity. It is also an economical option but may require some maintenance to the leaf springs from time to time.

DC Vibrators

Does your application deal with unloading trucks and hopper bottom trailers? DC vibrators are your ticket to achieving cleanout and eliminating costly carryback.

DC Vibrators are rated to operate in temperatures as cold as -20F (-28C).

There are a variety of force outputs available, from 80 lbf. Up to 3,500 lbf., for applications promoting consistent material flow in small hoppers or spreaders up to 12 cubic yard (35,000 lbs. max) dump beds.

The design of the DC vibrator comes in 12V or 24V and is permanently lubricated, making it a low-maintenance option. They also come fully enclosed, providing protection from environmental elements and increasing life out in the field.

The drawback with this vibratory solution is the cycle times, which vary depending on the force output your application requires. Each DC Vibrator model has an indicated cycle time for safe operation and maximizing the product’s longevity when operating in the field. For example, the MG-80 is rated for continuous duty, while the MG-200 can run on 30-minute intervals with 15 minutes break times between each cycle.

We have spoken a lot about electric-powered vibrator solutions, but what if your application requires the vibrator to run pneumatically?

Should an air-powered industrial vibrator be your only option, it should either be a standard unit that uses low-temperature lube, a coated vibrator model with dried airlines that do not require lube, or a turbine or rotary ball vibrator that does not require any lube at all. While low-temperature air lubricants do exist and help pneumatic vibrator operation in low temps, the tendency of airline freeze-up is a drawback for using pneumatic vibrators in cold environments.

If your application fits into this type of operational environment and you’re unsure which option would work best, we are happy to give you a hand in making the best decision to keep your material moving. Contact our team today.

Until next time, Movers & Shakers!

Follow us:

Share this blog post: