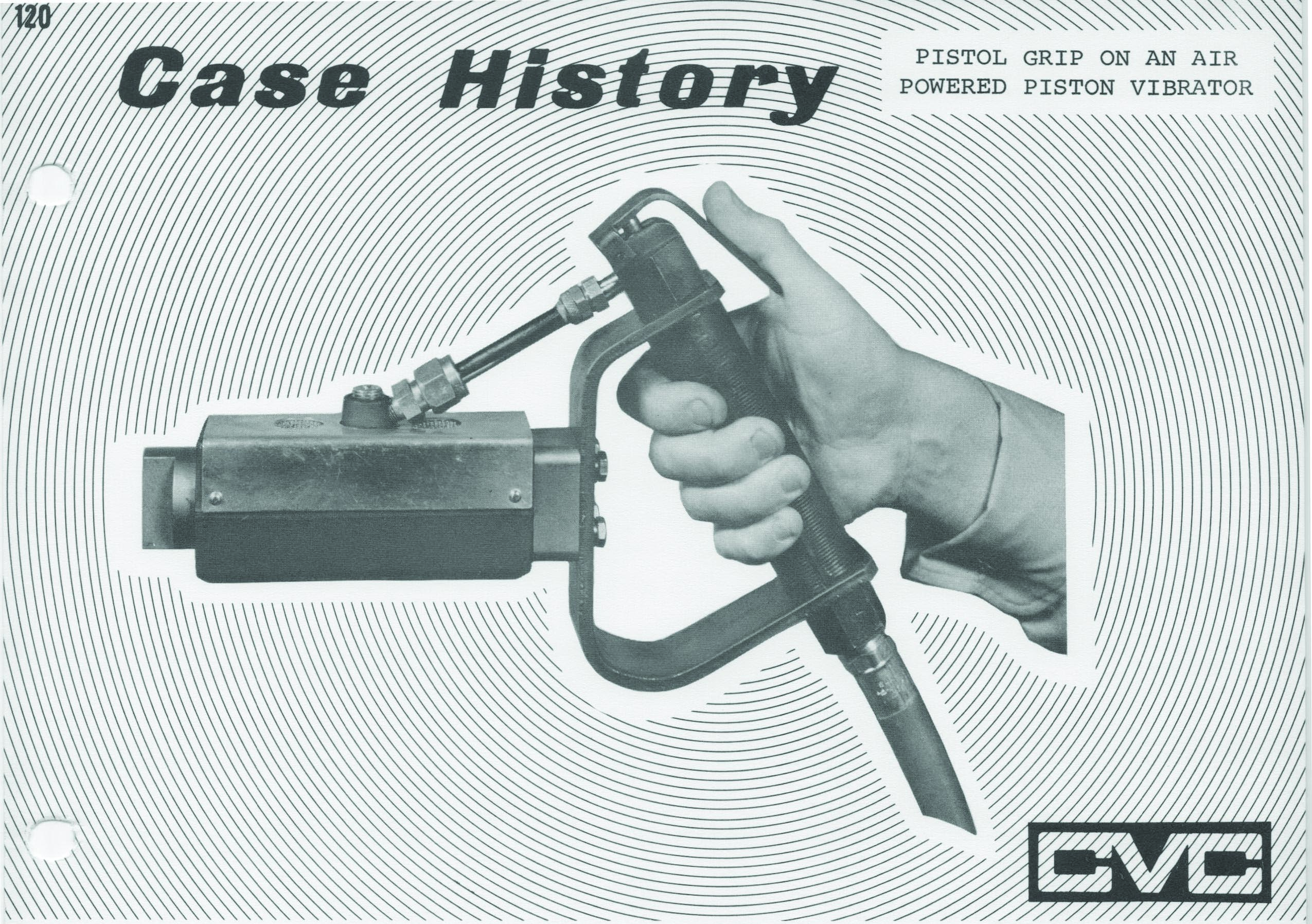

Vibration Force: Is Faster Actually Better?

By CVC Team

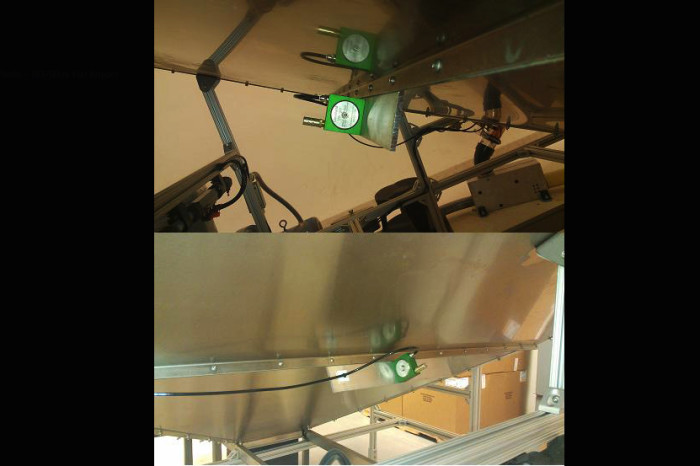

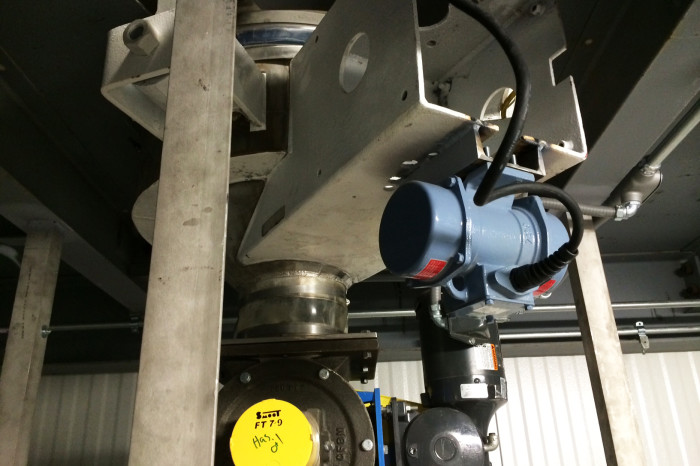

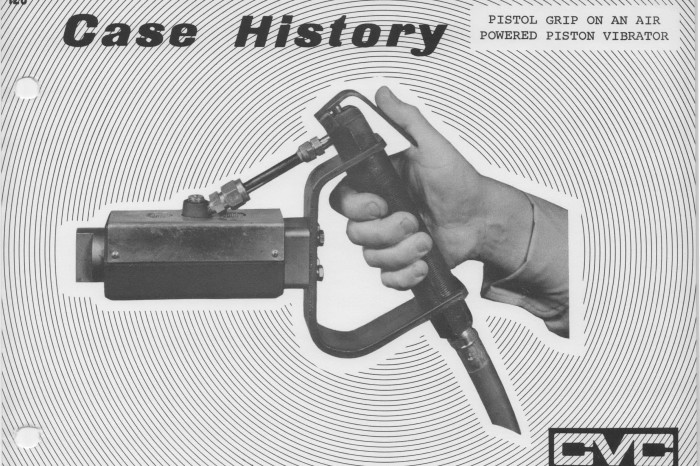

I have attached some photographs of a couple vibrators returned to Cleveland Vibrator for evaluation over the past year. It’s pretty clear that these units were not operated as per our operation manuals would instruct. Human nature causes us to try and make something work better or faster, we are the products of an an instant gratification way of life. We believe that products can work up to our lofty expectations even though we know it will work best to follow instructions in a user’s manual and to operate the product as instructed. As we used to hear at the beginning of the Six Million Dollar Man TV show many years past,”We have the technology to make it bigger, faster and stronger.” This hold true in many cases, especially relating to air piston vibrators, we shorten the life of the vibrator by believing we can use such technologies to override suggested operating specs. Read More…

Share this blog post: