Which Industrial Vibrator Works Best for Cold Temperature Applications?

By CVC Team

Previously, I wrote a blog about industrial vibrator options for hot temperature applications like transfer chutes in forging facilities or installations on cope & drags in a foundry. But what about those applications on the other end of the temperature spectrum?

Let’s talk about those cold environment applications like outdoor installs on a silo, chute, or load-out spout in geographic locations that face frigid temps, hopper bottom trailers delivering goods when there’s snow on the ground, or within facilities that do not have climate control.

When frigid temps are a factor, we lean towards supplying an electric vibrator option for material flow issues. Electric industrial vibrators do not require compressed airlines to operate, which is the biggest drawback when using pneumatic vibrators for these application environments.

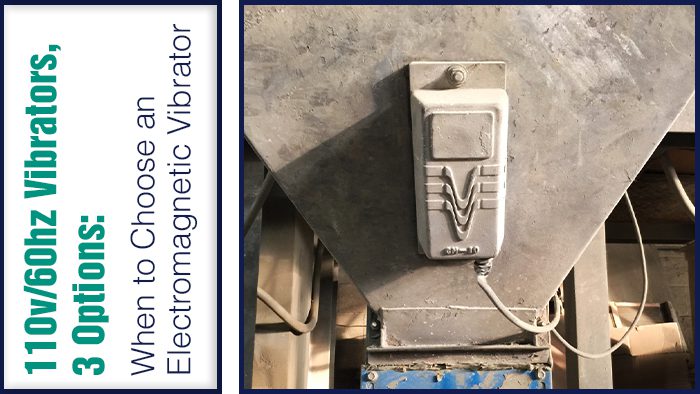

Between RE Rotary Electric Vibrators, CM Electromagnetic Vibrators, and DC Vibrators, plenty of voltage options, force outputs, and frequencies are available.

Read More…Share this blog post: