How Hoppers Can Improve Performance of Feeders & Screeners

By Jack Steinbuch

Hoppers can aid in the performance of material handling equipment, plus provide health and safety benefits for your workforce. To begin, we will review the advantages hoppers can provide to improve the performance of feeders and screeners for bulk loading applications.

Okay, so what is a hopper?

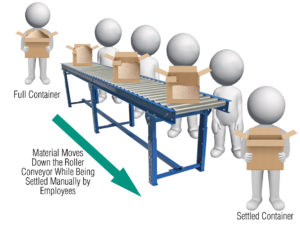

Hoppers can be stationary with steeply sloping walls to allow free-flowing material to discharge onto the feed tray. Due to their steep walls, these hoppers can have a high dump height, depending on the volume. For lower dump heights and/or poor flowing materials, a vibrating hopper is a great solution. The hopper is attached to the vibrating body and the vibrators are then upsized to compensate for the increase in vibrating weight. The material is fed from the hopper onto the equipment.

Read More…

Jack Steinbuch retired in 2021 following a decades-long career with The Cleveland Vibrator Company, where he served as a Sales Engineer for more than 36 cumulative years. His background also includes extensive experience in the manufacturing industry as a Senior Application Engineer, and throughout his tenure with our team he contributed in both sales and managerial roles. Prior to his retirement, he held the position of General Sales Manager.

A graduate of The University of Toledo with a BSCE, Jack is highly regarded for his expertise in sizing vibratory screeners, feeders, and vibratory drives for tables and other equipment. Known for his dedication to customer service, he has always emphasized the importance of recommending the right solution for every application — even when that solution did not come from The Cleveland Vibrator Company.

Outside of work, Jack enjoys spending time with his family, especially his grandchildren. An avid sports fan and participant, he enjoys golf and spent many winters as a league bowler. With his retirement planned for the end of September 2021, Jack looked forward to spending future winters vacationing in Florida.

Share this blog post: