Brake. Don’t Break.

By Craig Macklin

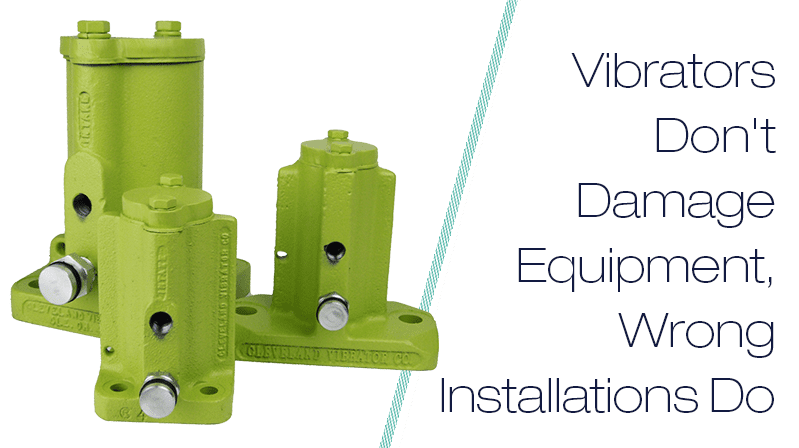

To the casual observer, Vibratory Equipment might look like pretty simple stuff. You just slap some vibrators on the thing to make it shake, right? Anyone can make that! Well, as we’ve seen in some other detailed posts from Jack Steinbuch, there is more than meets the eye to designing and building something that will work and last.

One design feature that we have offered and recommended in the past is the Dynamic Brake. I say that we offered in the past because we are now moving to just make Dynamic Brakes standard features. We recognize that many folks may not know what a Dynamic Brake really does in order to see it as a good option to add. However, as you will see in the explanation and video here, it is more than a good option. It is the right way to build controls for vibratory equipment. We feel so strongly about doing things the right way. So, we are now just including it as standard feature.

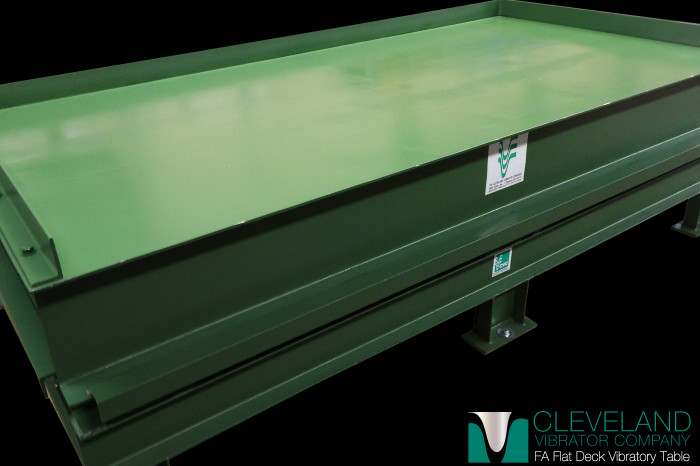

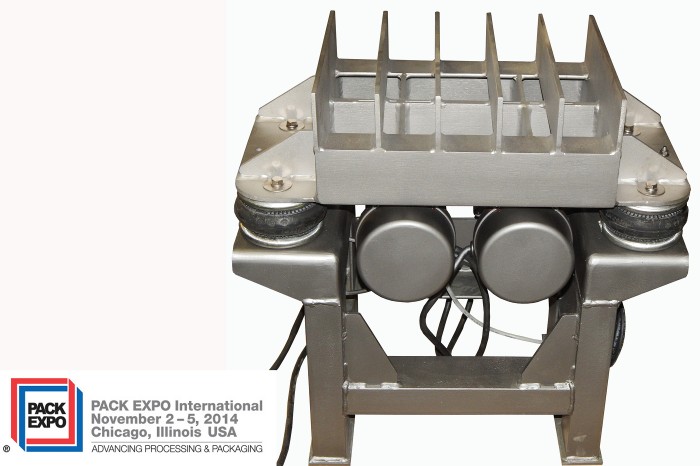

To explain the Dynamic Break, we need to start with a quick review of the vibratory motors that make the equipment work. A vibratory table, feeder or screener uses two rotary electric vibratory motors (or shaker motors) that counter-rotate. Read More…

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Share this blog post: