After reading some of our very informative blogs about vibration applications on hoppers, you probably learned that vibrators don’t damage equipment, wrong installations do. Those blogs described how critical it is to size the vibrator for your hopper applications and the importance of using a stitch weld to adhere the vibrator mount to the hopper wall. Now, I would like to provide some engineering support discussing why stitch welding is essential and further insight into how vibration works to improve material flow inside a hopper.

First, let’s talk about how vibration improves material flow inside a hopper.

I like to compare material flow issues in hoppers to a tiny game of Tetris on a grand scale. Those little particles, powders, grains, etc., are not perfectly round. They have little nodules, rods, hairs, and other surface imperfections – they also do not have a coefficient of friction of zero. Instead, the material is shaped like tiny 3D Tetris blocks with glue on the outside. Once the material is poured into a hopper, they can, and will, find a way to orient themselves to the other particles in a way that causes them to fit together like a hand in a glove. A hand that is also very sticky.

Applying vibration to the hopper wall violently forces the material to move. The vibration breaks the orientation bond apart and allows the material to flow again. When vibration flexes the hopper wall, the material breaks apart.

Second, we’ll discuss the importance of properly sizing your vibrator.

Ultimately, the goal is to flex the hopper wall without causing a crack to develop. Sizing is essential to achieve the proper flex without damaging your equipment. Proper sizing of your vibrator for your hopper application relies on the following:

- Size of the hopper

- Thickness of the hopper wall

- Material of the hopper wall

- Type of material stored in the hopper

- Other variables unique to your application

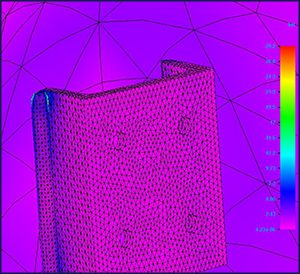

These factors determine which vibrator will provide deflection of the hopper wall that stays in the elastic deformation region of the hopper wall material’s stress/strain diagram. Too much force and the hopper wall will plastically deform with immediate permanent damage. Too little force and the hopper wall will not flex enough to cause the material to break apart.

Vibrator installation and how it works.

The Cleveland Vibrator Company provides a mounting channel to deliver the vibration force to the hopper. To protect your investment and equipment, we recommend stitch welding this mounting channel. Then, bolt the vibrator to the mounting channel. The mounting channel provides an accessible way to install and replace the vibrator while also transferring the force generated from the vibrator to the hopper wall. The vibrator creates a cyclical force pattern that deflects the wall toward the inside of the hopper, as well as pulls outward. Any force applied to the hopper will result in stress internally, which will transfer to the material.

What is Fatigue Failure?

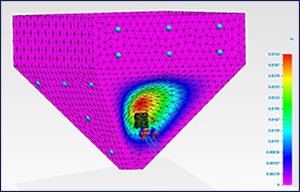

Applying vibration in a cyclical manner can lead to fatigue failures. Fatigue failures are the number one reason for crack development in hopper walls. The length of time the wall lasts before fatigue depends on many factors. But, the number one factor for premature fatigue failures is that a vibrator mount is incorrectly welded.

One common misconception is that the more weld applied, the better. While it is true that more weld will provide more area to withstand the vibratory force and reduce the stress in the welded section, the additional weld, especially at the corners of the mount, will also constrain the hopper wall, not allowing it to flex. This constraint at the corners will result in stress riser development in the hopper wall.

Stress risers are where the wall will fatigue and fail first, leading to cracks shown in the photo to the left. For this reason, the mounting channel must be stitch welded with the corners left free.

Of course, there are many more variables to consider to understand the complete picture of forces and stress development. Look for more blogs soon about this topic, including how to further reduce stress in your hopper walls and how to properly repair a hopper wall once it has failed.

Until then, we’re happy to answer any questions you have about the proper installation of your industrial vibrator – contact our team of vibration experts!

Share this blog post:

Follow us: