If you’re new to vibratory equipment and vibratory feeders, you may be wondering, “How does a vibratory feeder WORK?” It’s a fair question, and one we hear a lot from people who aren’t familiar with this type of equipment! It’s a completely horizontal solid tray or tube with seemingly no moving parts. Still, the material moves steadily from one end to the other. But, HOW?

Here’s the secret:

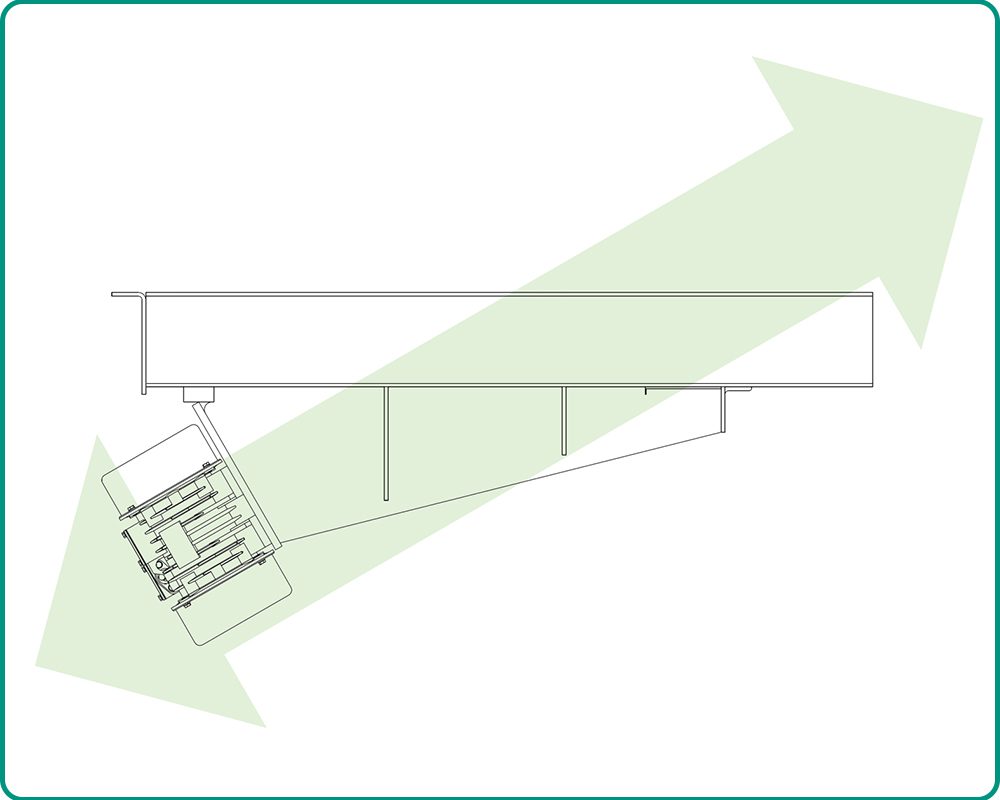

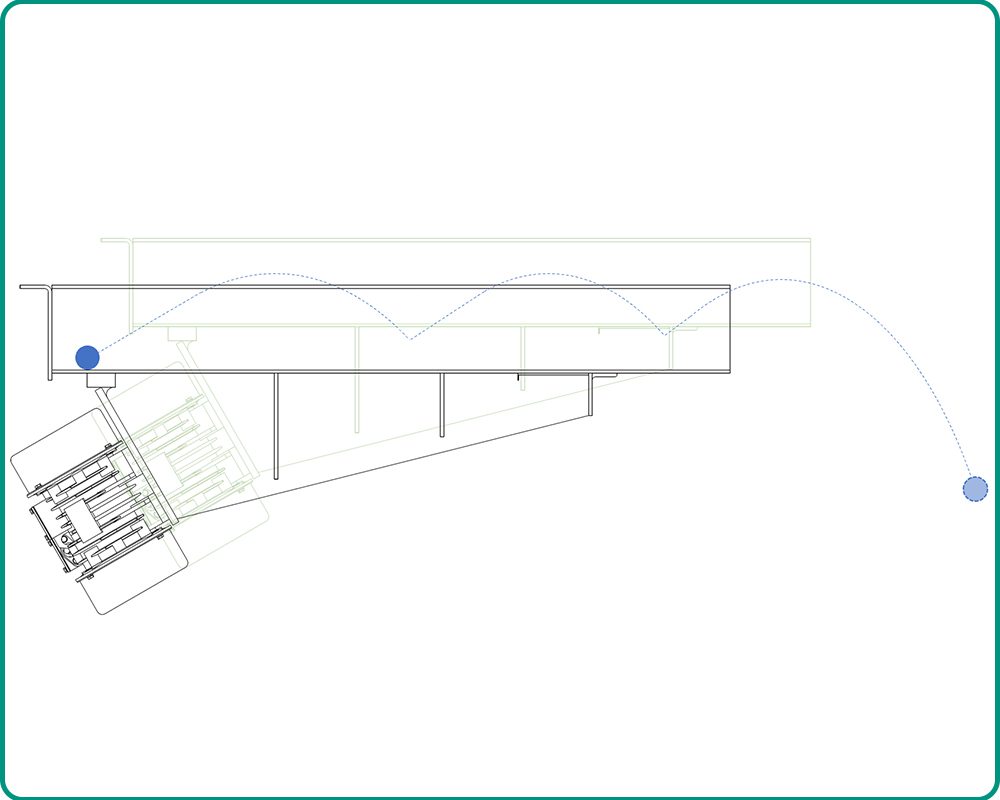

To move material horizontally from one place to another, the vibratory drive is mounted to the tray or tube at an angle, causing the particles to hop up and forward. The video below does a great job of outlining this process in detail.

So what looks like a steady stream of material somehow magically flowing across a horizontal tray is actually a huge number of tiny little forward hops that happen so quickly our eyes have a hard time telling they’re “hops” instead of a steady stream!

Vibratory feeders are an ideal solution for moving fine or abrasive particles, because:

- There are no moving parts in contact with the material

- The tray is solid, meaning there are no gaps for small particles to slip through

- There are no critical clearances to be worn open over time

But, vibratory feeders are not just for small particles! Vibratory feeders are also an excellent, low-maintenance choice for moving all shapes and sizes of material at a repeatable rate. This versatile piece of equipment can streamline your production process by handling tons of material at a time.

The secret to achieving low-maintenance, reliable material flow is in the design of the vibratory feeder and the drive selection. In short, different materials respond best to different vibratory forces and frequencies. The Cleveland Vibratory Company has 95+ years of experience choosing the force, frequency, and physical feeder design to produce the best results with your material. We also offer free material testing to ensure the solution we provide is the best for your unique application.

Benefits of choosing a Vibratory Feeder from The Cleveland Vibrator Company

Are you still on the fence about incorporating a vibratory feeder into your operation? Here are five benefits for investing in a vibratory feeder with The Cleveland Vibrator Company:

- Increase your production rates with a reliable, low-maintenance vibratory solution

- Increase your product quality with reliable and repeatable feed rates

- Pneumatic and rotary electric vibratory options with various forces and frequencies available for almost any application

- Every piece of equipment is tailor-made to perfectly fit your application

- Top-notch customer service from a team of knowledgeable vibration experts for your selection and installation needs

Do you want to learn more about how a vibratory feeder can benefit your operation? Contact us today to see how our vibration experts can solve your material feeding problems!

Kate joined The Cleveland Vibrator Company in 2020 with experience in Application, Product, and Sales Engineering for industrial equipment and component manufacturers. With a B.S.E. in Mechanical Engineering from Case Western Reserve University, she’s now in our Sales Department and specializes in finding custom technical solutions to unique applications.

When she’s not shaking things up in the world of industrial vibration, Kate self-describes as a giant geek who enjoys reading science fiction books, finding projects to over-engineer in her household, and spending time with her husband and sons. You can find Kate outside hiking or horseback riding in her free time, followed by the occasional craft cider or beer!

With expertise in both engineering and application-specific topics, keep an eye out for this vibration expert to provide some great insight into all things #VibrationEducation!

Share this blog post:

Follow us: