When I was young(er), I remember hearing that robots would replace everyone’s jobs. Almost immediately I thought:

It seems like a good job will be building robots.

Who is Fastfeed Corporation?

Due to The Cleveland Vibrator Company’s recent acquisition of Fastfeed Corporation, I am proud to realize that childhood dream! Fastfeed Corporation is a manufacturer of unique automation systems for high volume and high-speed applications in assembly, sorting, and packaging. Coming at a time when the unemployment rate in the U.S.A. is at ~4%, it is critical to high volume manufacturers to eliminate reliance on humans to handle repetitive functions on production lines.

That’s where the automation offered by Fastfeed comes into play. As a result of streamlining applications in assembly lines, sorting lines, and packaging stations, opportunities for automation can be easily identified and achieved.

What does Fastfeed Corporation do?

Okay, Fastfeed is not Fanuc, an actual builder of robotics, but the concept plays, and we do use robotics in the automation systems. Small, but long-established and capable, Fastfeed builds and services automation solutions and components at multiple tiers of complexity. These solutions include:

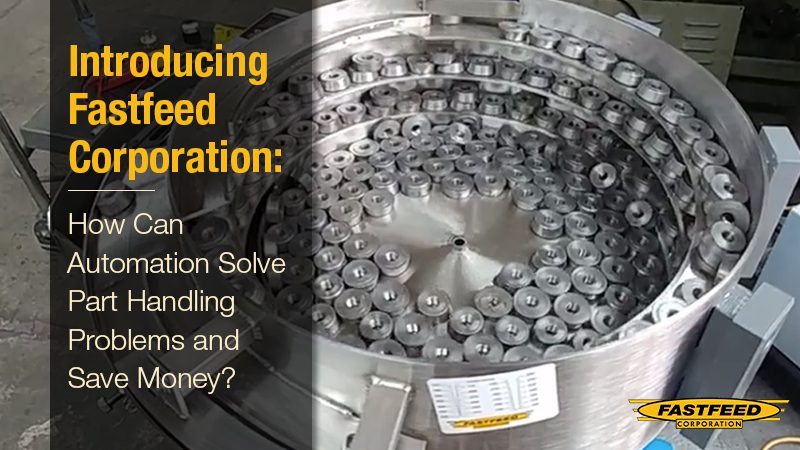

- Vibratory bowl feeders

- Fastener installation systems

- Weld nut and weld stud feeders

- Part feeding systems

- Turnkey automation systems

- Aftermarket bowl feeder rebuild and retool services

Fastfeed Corporation provides products and services ranging from the rebuild and repair of critical part handling components such as bowl feeders, to the construction of new bowl and inline feeders, to manufacturing fastener feed systems and weld or die cells, to integrating fully turnkey automation cells that align, orient, feed, quality check and assemble the infeed of multiple bulk parts.

How can the Fastfeed Corporation help your operation?

This fantastic addition to The Cleveland Vibrator Company family of products has been “building robots” for decades. Most importantly, integrating these systems into your process will increase the reliability and efficiency of your operation. As a result, you avoid the headache of trying to fill open positions and save valuable production time and money. For example, do you want to:

- Present a weld nut perfectly for a robotic welder to weld to a stamping for 24 hours/day?

- Sort bulk bolts by length and thread before packaging?

- Assemble three odd-shaped parts into pump handles?

- Get your old Bowl Feeders working like they used to or better? Or converted to handle new parts?

Now, we can do it! The possibilities are endless. We can build your “robot,” and you can avoid another expensive posting on a job board.

Stay in touch and learn more!

If you want to stay up to date with Fastfeed Corporation, keep an eye out for their new website coming soon: www.fastfeedcorporation.com

Until then, if you have questions about how you can save time and money by automating your process, reach out to our team! We’ll learn more about your application and design and manufacture the perfect custom solution for your operation: https://www.clevelandvibrator.com/contactus

Want more #VibrationEducation from our vibration experts? Check out our previous blog from Derek Stake, “The Engineering Perspective: How to Stop Fatigue Failure During Vibrator Installation“.

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Follow us:

Share this blog post: