This blog is the third in a series that has been dedicated to typical screening media that are installed in Vibratory Screeners with their advantages and disadvantages so you can be in a better position to assist us in the selection process.

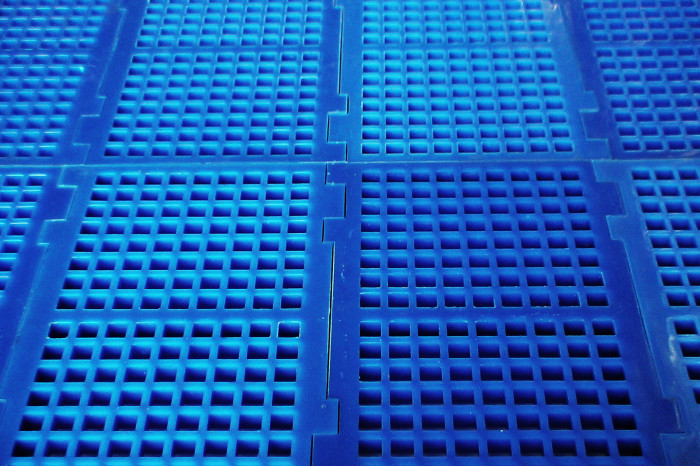

Polyurethane

This screening media has been gaining acceptance in sizing and dewatering applications. Polyurethane is a synthetic polymer that is either cast or injection molded into screen decks or panels/modules. They are somewhat similar to perforated plate as specifications are typically designated by the openings, there is a bar width (amount of material between the openings), centers (distance between the holes as well as staggered or straight line) and thickness. Read More…

Share this blog post: