Recently on a long weekend, I took the “Behind the Scenes Tour” of the C.F. Martin guitar factory in Nazareth, Pennsylvania. During the tour, the six of us in my group got to see pretty much the whole guitar building process from wood coming in the back door to the final setup of the completed instrument. Along the way we spent a few minutes talking with the guy that actually hand selects the wood for all the Custom Shop guitars, the customer works with a Martin guitar distributor, customizes an instrument, and starts the process. This gentleman reviews the order’s specifications and gets to look through Martin’s selection of some of the most beautiful wood you’d ever want to see to find just the right set to match up with the order. Custom shop orders start with the basic guitar body style and build on from there, sort of like what Cleveland Vibrator does with its product line. Cleveland Vibrator is very customer-driven; the customer knows their business, process, and goals, Cleveland Vibrator asks questions, listens, and often conducts testing, then offers a solution to accomplish those goals. Similar to Martin Guitars on the “custom build your guitar” portion of their website, modifications to Cleveland Vibrators products are available.

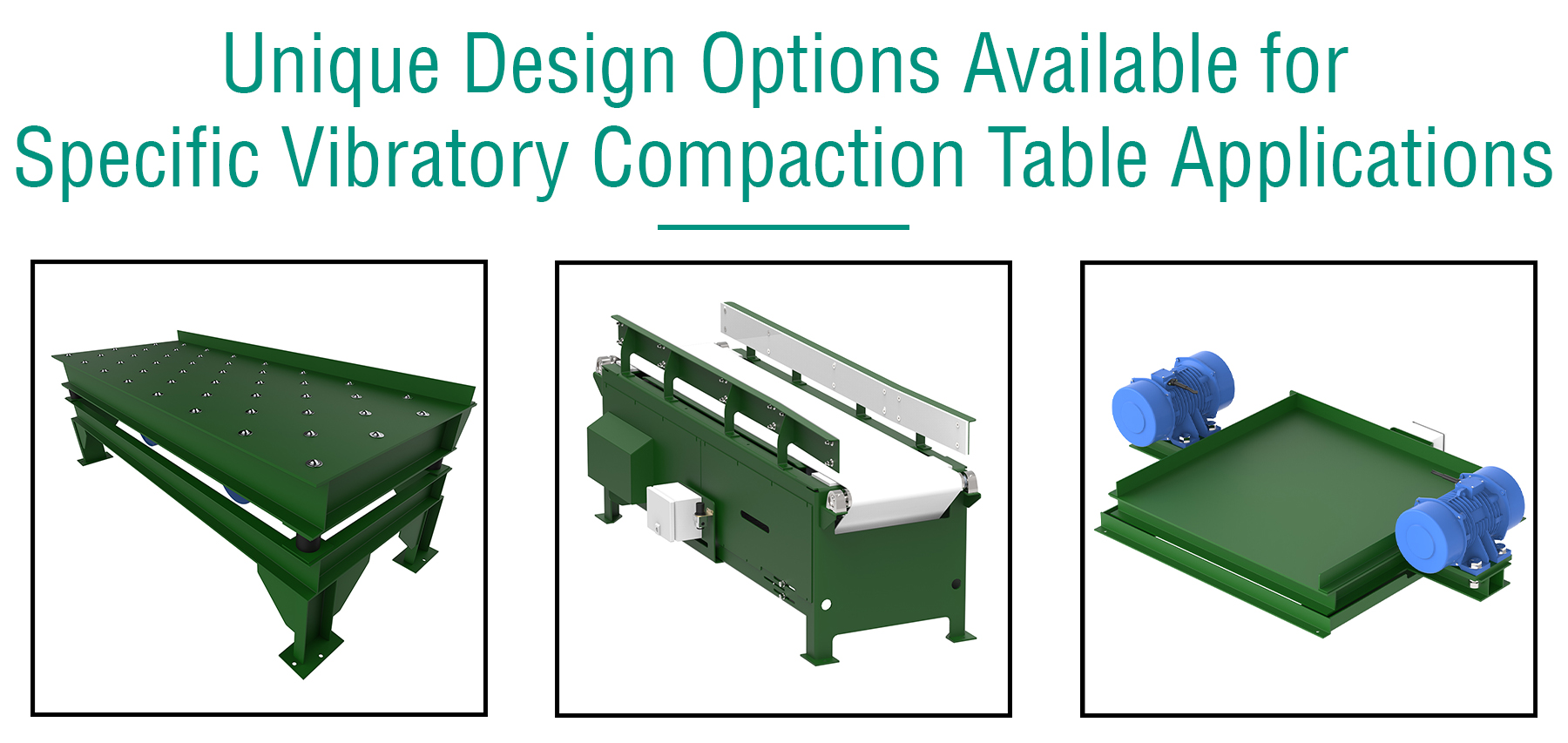

A good example of a product that is often modified by customer requirements is the vibratory table. Basically, a table is designed to vibrate linearly in the vertical direction. From this very basic concept, there is almost an infinite number of options and variables available to accomplish the customer’s goal, regardless of how simple or Read More…

A good example of a product that is often modified by customer requirements is the vibratory table. Basically, a table is designed to vibrate linearly in the vertical direction. From this very basic concept, there is almost an infinite number of options and variables available to accomplish the customer’s goal, regardless of how simple or Read More…

Share this blog post: