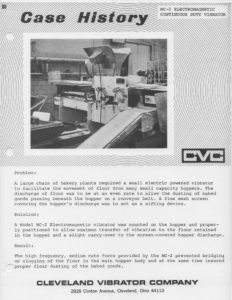

Working for the Cleveland Vibrator Company, you can imagine how many times I get the question, “what exactly do you mean by vibrators?” It’s a question I answer with great pride and enthusiasm… and maybe add a little bit of humor for good measure. When I go on to explain just how important vibration is across so many industries, the shock factor withers away and people are engaged in the conversation, wanting to learn more about it. There’s a couple of things you should know about industrial vibration and why it may be one of the coolest fields to work in, here’s the short list to get you started:

It’s Diverse – It’s true. Industrial vibrators can be found on the side of bins, hoppers, silos, barges

It’s Diverse – It’s true. Industrial vibrators can be found on the side of bins, hoppers, silos, barges

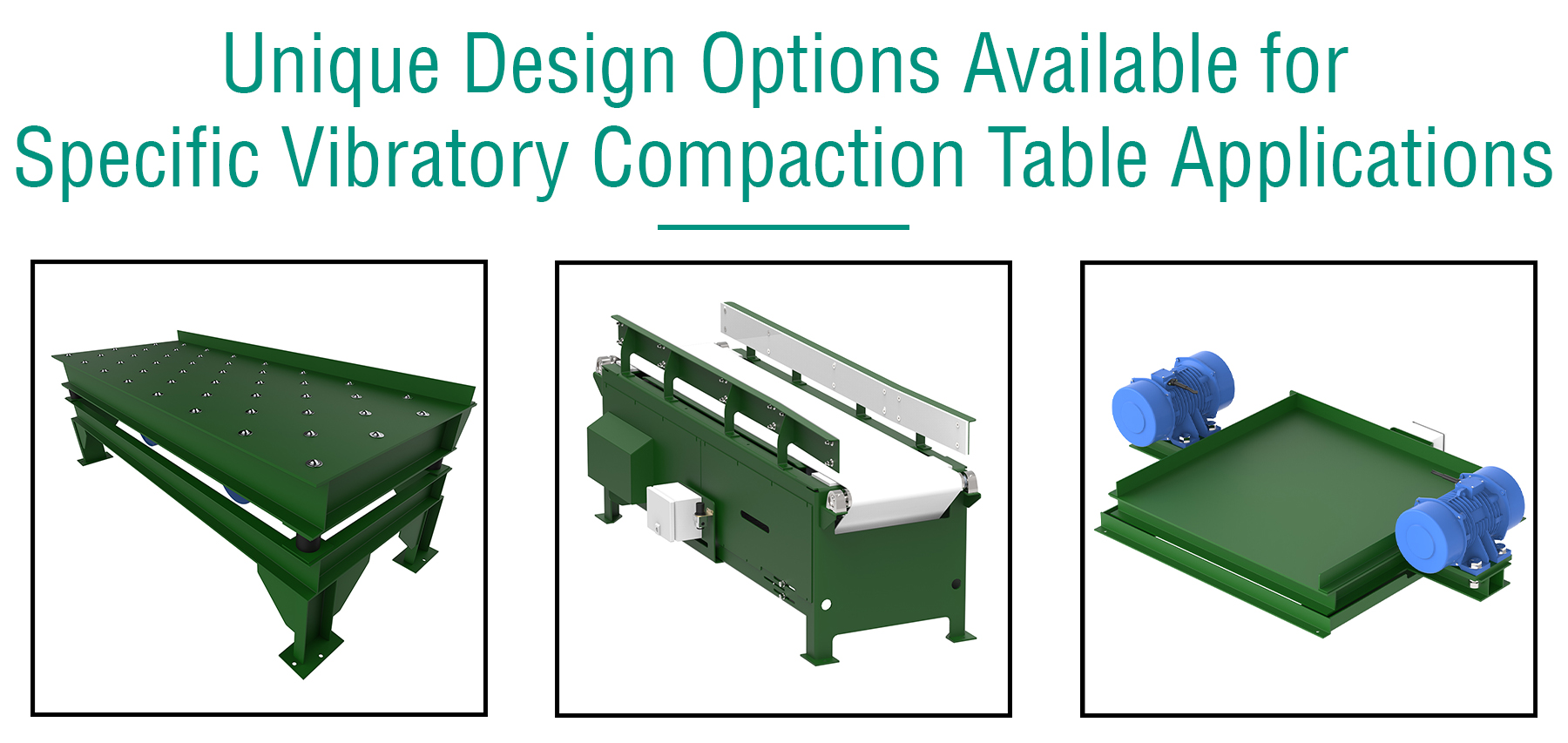

and on screening, conveying and compaction equipment. Have you passed a large dump truck lately on the highway? I’d venture to bet there may be a DC vibrator hiding away underneath the body Read More…

Share this blog post:

One of the options available when it comes to material handling and unloading dry bulk barge hoppers or vessels is vibration. These externally mounted

One of the options available when it comes to material handling and unloading dry bulk barge hoppers or vessels is vibration. These externally mounted