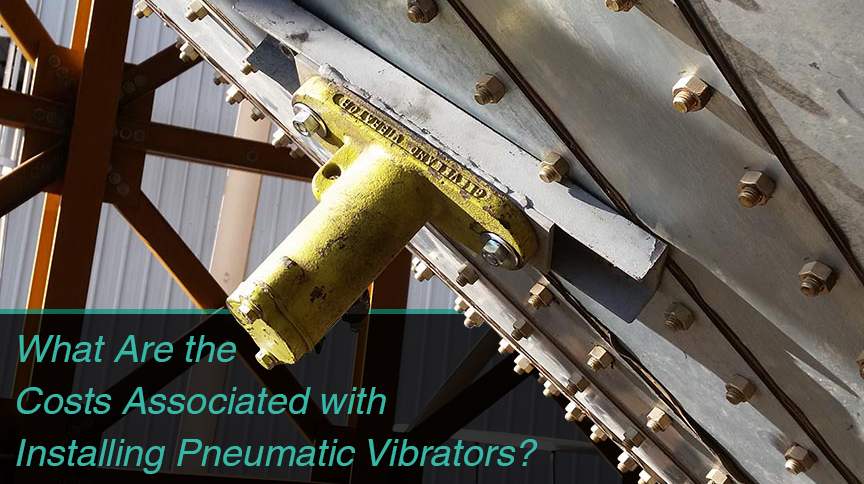

When it comes time to review solutions to the material flow problems inside the hopper, pipe, or chute, there are a few things to keep in mind when putting together a budget for the project. Besides the vibratory flow aid itself, there are additional components required before installing the unit. We will discuss these items and estimated costs of acquiring these components. Here is the shortlist:

- Industrial vibrator – pneumatic piston vibrator, single impact air knocker, pneumatic turbine vibrator, pneumatic ball vibrator

- Safety cable

- Mounting channel or plate

- Hose to connect the vibrator to the on/off valve

- On/off valve

- Hose to connect on/off valve to air prep component (filter/regulator or filter/regulator/lubricator)

- Lubricant (if necessary)

Depending on the size of the hopper or piece of equipment that the pneumatic vibrator is going to be installed on, the price of the vibrator itself can range from about $100 to as much as $10,000. But, within that range, the vast majority of the units are going to be between $100-$1000. Read More…

Share this blog post: