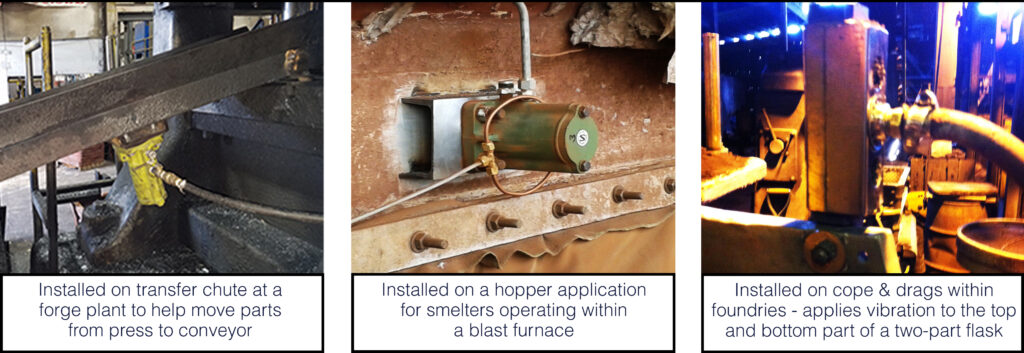

Casting facilities pour molten metals into molds that require vibration to enable material flow and release air from the molten metal during the cooling process. Hot Forging Facilities feed metal ranging from 800 degrees Fahrenheit to 2200 degrees Fahrenheit, depending on the material they’re producing which may require vibration for their transfer chutes. These are just a few examples of material flow locations that vibration can be used within these facilities.

What is the one thing these applications have in common? Heat.

When a customer comes to us asking about a vibratory solution which will be exposed to extreme heat conditions, we often ask them to consider the following environmental factors:

- Is the vibrator going to be installed inside or outside of the facility?

- What types of temperature control methods are being used?

- What is the actual ambient temperature of the environment in which this vibrator will be operating in?

Why are these questions important? Well, a couple of reasons. Our team has expansive knowledge and industry experience that we can confidently tell you how temperature will affect the mounting channel, welds, and the vibrator unit. We also can tell you if a vibratory unit is your best option.

The heat that can occur within a facility from creating steel, pouring castings, or forging metal will raise the ambient temperature of the environment that surrounds the processes. This can negatively impact the operation of the vibratory unit operating within this environment.

One big factor to consider is when metal is heated to extreme temperatures, it expands. This is particularly important when considering which type of vibrator will work best for your application.

Our team has a few options for extreme high temp operational environments available. Let us look at what they are:

VMS/VMR Impact Piston Vibrators

Pros: This product is durable and built with high-quality components. It has a high environmental tolerance and high force impacts.

Cons: The presence of heat affects the moisture content of the air, this can cause the vibrator to stall. The base of the unit can also be impacted by the heat and may become weaker over time, as well as the gaskets and seals of the unit. Cleveland Vibrator has high temp gaskets available to help alleviate this issue.

Pros: The heat expansion of the metal will not affect the components and operation of the ball vibrator. It is an economical option. It is an effective vibrator solution for gravity-assisted chute or pipe material flow applications.

Cons: It is a loud option so noise level compliances may pose an issue. It is not as efficient on compressed air. You can expect a shorter operational life expectancy in harsh environments.

SA-EP Spring Activated Air Piston Vibrators

Pros: They are easy to attach to cope and drags and are a low-cost vibratory option. They are tried and true in the foundry industry with decades of operational success behind them for serving this industry. Cleveland Vibrator has application reports and case studies dating back 80+ years, showcasing this vibrator and its success in the foundry industry.

Cons: The heat can weaken the spring that activates the piston impact within the unit, ultimately resulting in shortened life of the unit out in the field.

Pros: This product line is rated for operation in temperatures of up to 450-degree Fahrenheit. They are virtually silent during operation and use low air consumption.

Cons: They are a more expensive option than the economical Ball Vibrator Series and have limited force output options currently available.

CBS Core Molding Machine Vibrators

Pros: The body of this model is bigger and more robust which helps it stand up to harsh conditions longer than a smaller unit, such as the SA model, would.

Cons: Similarly to the SA Model, it’s spring-activated which due to the conditions with heat present, may cause the spring to fatigue over time.

UH/UHVM Portable Piston Vibrators

Pros: It’s portable. The simple mounting bracket can be installed on multiple areas of a casting, giving you the ability to vibrate certain problematic areas when necessary.

Cons: Similarly to the Piston Vibrators, the presence of heat can affect the moisture content of the air, causing the vibrator to potentially stall over time.

We feel it important to note that extremely high temperatures can impact the integrity of the bolts used for installing vibrators to their mounting channel. This issue is common and unavoidable, regardless of which vibrator type the customer would choose.

Do not sweat finding the perfect vibratory solution for your challenging application on your own! Contact a vibrator expert directly today, we have got you covered.

Until next time, Movers & Shakers!

Contributors:

Mike Stratis – Sales Team Lead, The Cleveland Vibrator Company

Derek Stake – Director of Operations, The Cleveland Vibrator Company

Follow us:

Share this blog post: