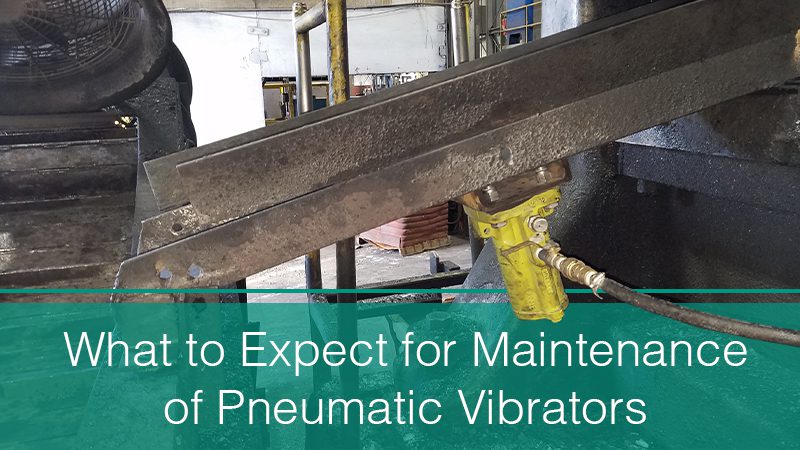

What to Expect for Maintenance of Your Pneumatic Vibrator

By Craig Macklin

As my incredibly knowledgeable associate, Mike Stratis, wrote a blog about accessories to consider for installing an air-powered vibrator, I thought I would provide a follow-up piece to discuss what to expect AFTER the install. As with any equipment, pneumatic vibrators and their supporting accessories require love, attention, lubrication, and cleaning. Here is what to expect if you want to get the longest and most consistent life out of your pneumatic vibrator, whether a piston, turbine, or ball.

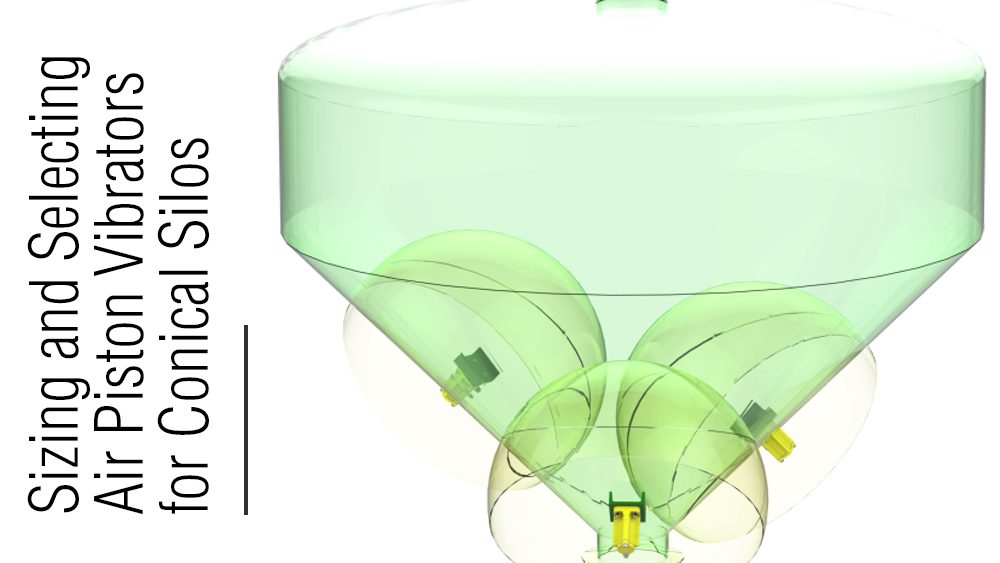

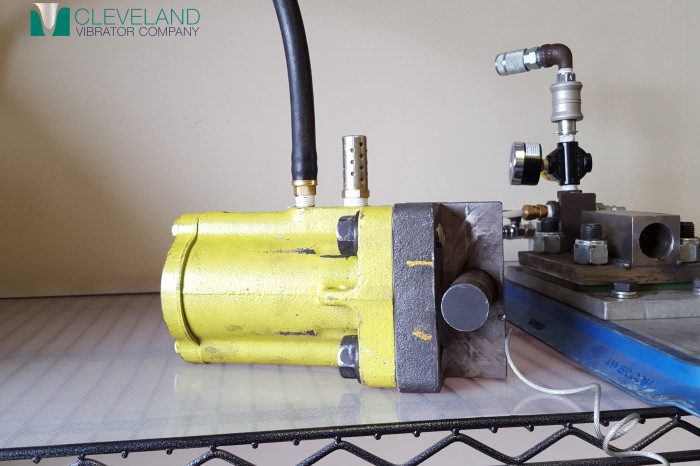

Air Piston Pneumatic Vibrator

Lubrication

Firstly, you must check your lubricator with some frequency. If you operate continuously, you might check and/or refill every 1-3 weeks. If your use is intermittent or infrequent, you might schedule on a 1-4 month basis. The use of internal coating in the vibrator can reduce or remove the need for lubrication. But, coatings without lubrication will typically wear out faster than a coated or uncoated piston vibrator that is properly lubricated. Depending on the size and duty cycle of your vibrator, you might use a pint of lubricant every 2 weeks – 2 years. We recommend our MXR-12 VibraLube, which is 10W-NR.

Read More…

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Share this blog post: