Things to Stick a Vacuum Mount Vibrator On, Part 1

By Craig Macklin

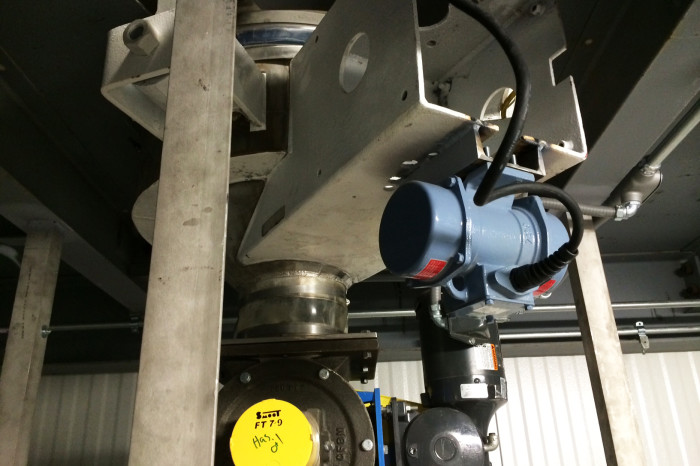

Recently, Cleveland Vibrator Co. has been working on developing a series of Vacuum Mount Systems for our vibrators. Typically, these are used for helping flow or clean out on portable hoppers, bins, IBCs, hopper bottom and belly dump trailers, or railcars. However, our newest release, the Mini Turbine Vacuum Mount series, has a variety of other fun applications that we can demonstrate in our very own plant here.

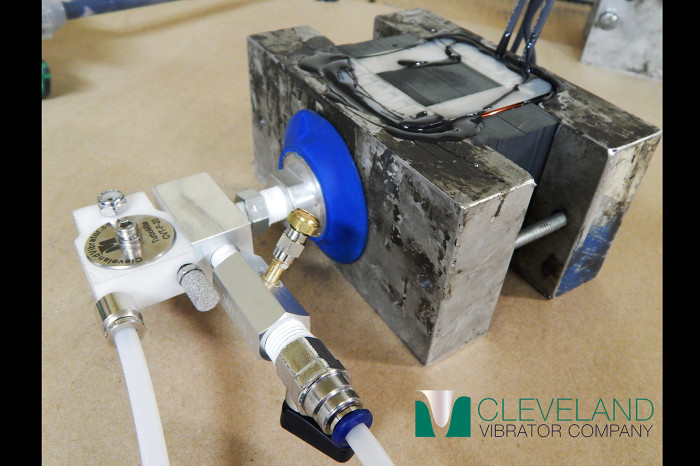

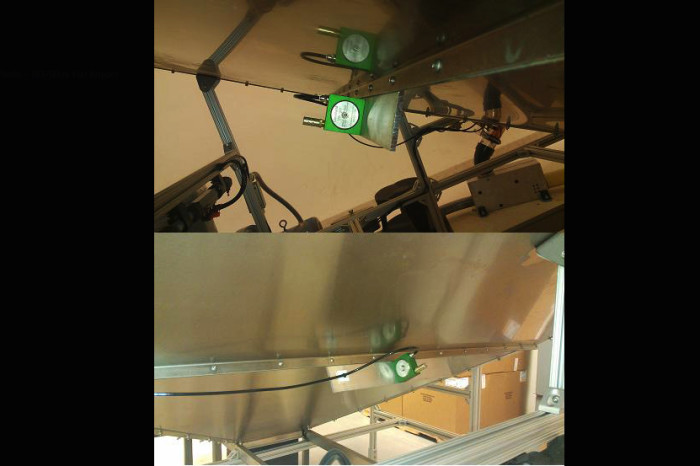

The first application to look at here is the Vacuum Mount CVT-P-20 being used in our coil making process. Our line of CM Electromagnetic Vibrators uses encapsulated coils that we make in house. In that process, we use vibration in order to settle epoxy around the coil in a mold, removing air bubbles and eliminating voids. Typically, we have used our VJ Vibratory Jogger tables in order to do this. However, in the video linked here, you can Read More…

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Share this blog post: