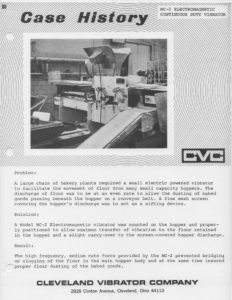

It seems to me that most applications start with a problem to solve; improve a process, simplify an operation, increase yield or throughput, or remove a bottleneck. This problem could be as simple as placing the appropriate size pneumatic piston vibrator on the side of a hopper. It could entail getting the right air-cushioned vibrator such as the 1200 VMSAC or maybe a single impacting SI vibrator along with the matching SMP mounting channel and controls. Or the problem could be broader with concerns regarding the process or task to be accomplished and the design envelope into which the solution must fit and then interface with other equipment.

Regardless of the problem, options and choices are always good.

Often with equipment one of the first things that comes up in initial discussions is the design height or discharge height of the unit. With vibratory feeders (EMF) and screeners (EMS) there’s always a concern about the product discharge height, as the equipment is often feeding material downstream to other devices. One of the options that impact the design and therefore the height of the unit is the location of the vibrators. Typically on vibratory feeders and screeners, the default Read More…

Share this blog post: