Six Proven and Effective Seasonal Uses For Your New DC Truck Vibrator

By Zach Church

When there is winter there is snow and ice, a sad fact of life. It’s up to the snow and ice management teams to ensure that roads and parking lots are safe for travel. For those in the snow/ice management business, DC vibrators are an essential tool that evenly distributes salt and de-icing materials.

But as the snow melts and the weather warms up, many overlook the fact that these vibrators are far from being just snow season tools. You can use DC vibrators across numerous industries year-round, making them versatile pieces of equipment.

Here’s how your DC vibrator can go beyond just the winter season:

LANDSCAPING MADE EASY

In the spring, when the landscaping season kicks into high gear, DC vibrators make the transition seamless. Whether you’re spreading mulch, gravel, or topsoil, a properly equipped truck ensures these materials flow smoothly and quickly from your hopper or dump trailer. This increases your efficiency, reducing the need for manual labor and rework. The same vibration that helps salt flow freely in the winter can also help your soil or mulch from clumping, making it easier to spread across large areas.

PRO TIP: Just like in the winter, ensuring that your DC vibrator is appropriately installed and maintained is critical to preventing breakdowns during your busiest times. Regular checks of your mounting plate, bolts, and cables will keep your equipment running smoothly through any season.

AGRICULTURE APPLICATIONS

In the fast-paced world of agriculture, the versatility of our DC vibrators is a game changer for famers and agricultural professionals a like. Whether spreading fertilizer, seeds, or feed, having a reliable vibrator ensures consistent flow, preventing blockages and uneven distribution. This can be particularly beneficial during the planting season when time is of the essence and equipment downtime is especially costly.

PRO TIP: It is crucial to adjust the vibratory force based on the type of material being spread and the hopper being used. Heavier material and larger hoppers might require more force, while lighter, finer materials or smaller hoppers only need gentle vibration to keep things moving.

CONSTRUCTION AND AGGREGATES

In the construction industry, time is money. DC vibrators can efficiently spread aggregates like sand, gravel, and crushed stone. This is particularly useful in road construction and paving, where even distribution of materials is critical to the quality of the final product. When pouring concrete, a constant vibratory force can shake out air pockets and significantly reduce manual intervention. DC vibrators prevent materials from sticking to the hopper, keeping the project on schedule and your deadlines met.

PRO TIP: Be mindful of the hopper’s load and the density of the material being used. Dense materials, like concrete, might require stronger and more consistent vibration than something more porous. Additionally, monitor the spread rate to ensure that the vibratory force doesn’t cause material segregation or uneven distribution. Consider the position of the vibrator on the hopper or shoot. This will aid in the proper distribution of the material being spread.

WASTE MANAGEMENT AND RECYCLING

Within the demanding field of waste management and recycling, DC vibrators offer significant advantages to streamline operations. Whether dealing with organic waste, scrap metal, or end of year record shredding, these vibrators can help ensure that materials move smoothly down the hopper and into the shredder. This not only improves the operation’s efficiency but also reduces the risk of jams and bridging that can occur, leading to costly downtime.

PRO TIP: In harsh environments like waste management, it’s especially important to regularly inspect the vibrator and its components for signs of wear and tear. Keeping the vibrator well-ventilated and free from debris will extend its lifespan and ensure reliable operation.

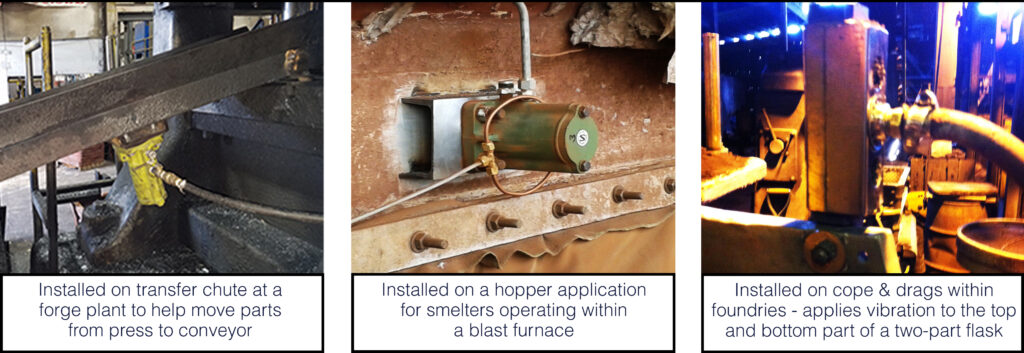

CUSTOM SOLUTIONS FOR UNIQUE APPLICATIONS

At Cleveland Vibrator, we understand that every operation is different, so we offer a range of DC vibrators designed to meet any need. From small tailgate spreaders to large heavy-duty hoppers, we can help you find the perfect solution for your specific application. And if your needs exceed our standard products, we’re always here to discuss custom solutions tailored to your unique challenges.

PRO TIP: Don’t hesitate to reach out to our team if you have a specialized application in mind. Our experts are always available to help you select the right equipment and provide installation and maintenance advice to keep your operations running smoothly.

VIBRATORS FOR EVERY SEASON

As you can see, DC vibrators are far more than just winter tools. Their versatility makes them valuable assets in a wide range of industries, from landscaping, agriculture, construction, waste management, and more. By choosing the right vibrator and maintaining it properly, you can ensure that your equipment performs at its best, no matter the season.

So, as winter ends and snow melts, don’t store away your DC vibrator just yet. Think about how you can use it in your other operations to save time and improve efficiency year-round. At Cleveland Vibrator, we’re here to help you make the most of your equipment, season after season.

If you have any questions or need additional assistance, don’t hesitate to contact us. Our team is always ready to help you find the perfect solution for your needs.

Let’s work together to keep your operations running smoothly, no matter the season!

Zach (quite literally) grew up in the industry – beginning way back to 1999 – when he began pitching in at his family’s company, which specialized in DC Electric truck and trailer vibrators.

In his sales role with Cleveland Vibrator, Zach uses that extensive industry knowledge to help expand sales and awareness of our popular DC-80 and DC-200 vibrators, which are designed to promote consistent material flow in spreaders and small hoppers.

Share this blog post: